What is a Thermoforming Mold: Types, What to Consider, and More

2025-09-08

Getting consistent, high-quality results when thermo molding plastic takes more than just heat and pressure; it all starts with the right thermo mold or tools. In this article, we’ll walk you through how thermoforming works, the different types of molds used in the process, and the key that brings it all together. Whether you’re new to the field or looking to upgrade your setup, this guide will help you understand the essentials that shape success in thermoforming.

| Table of Content |

1. What is Thermoforming for Plastic?

Thermoforming is a popular manufacturing process used to shape plastic sheets into functional products. It works by heating a plastic sheet until it becomes soft and pliable, then forming it over a mold using vacuum, pressure, or mechanical force. Once cooled, the plastic keeps the shape of the mold. This method is widely used in industries like food packaging, automotive, medical devices, and consumer products because it’s fast, cost-effective, and capable of producing both simple and detailed parts.

1.1. Thermoforming Processes: How Does It Work?

The thermoforming process begins with a flat plastic sheet, known as a thermoplastic, which is clamped and gradually heated to a temperature that makes it flexible. Once the material is soft enough, it’s shaped over or into a mold using one of several forming techniques, which we will discuss later.

After forming, the plastic is cooled, trimmed, and removed from the mold. The final product can range from disposable containers to durable parts like dashboards or panels. Let’s look at the most common forming methods in more detail.

1.2. Different Techniques of Thermoforming

Vacuum Forming

Vacuum forming is the simplest and most cost-effective type of thermoforming. After the plastic sheet is heated, it’s laid over the mold, and a vacuum is pulled from underneath to draw the material tightly against the mold’s surface. The air is sucked out, causing atmospheric pressure to press the plastic tightly against the mold surface. This method is ideal for shallow parts with simple shapes, such as blister packaging, food trays, and internal clamshell inserts. While it’s easy to operate and inexpensive, vacuum forming doesn’t offer high detail or tight tolerances.

Pressure Forming

Pressure forming builds on vacuum forming by adding compressed air above the plastic sheet while the vacuum is pulling below. This added pressure, often up to five times greater than atmospheric pressure, forces the plastic into fine details of the mold, even those with deep textures or sharp edges. This makes pressure forming a go-to option for parts that need a more finished look, such as appliance housings or medical equipment, and control panels. Although it’s more expensive than vacuum forming, pressure forming produces parts with better definition, tighter tolerances, and a more professional appearance.

Twin Sheet Forming

Twin sheet forming involves two heated plastic sheets formed at the same time, each over its own mold. Then, while still soft, the two sheets are pressed together, bonding at contact points through heat and pressure, or sometimes with the help of external pressure. This process creates a single, hollow part with high strength and rigidity. It’s often used for making pallets, air ducts, and cases where a hollow core improves durability or reduces weight. Twin sheet forming is more complex and requires advanced equipment, but the result is a strong, structural part that can’t be achieved with single-sheet methods.

Matched Mold Forming

In matched mold forming, the plastic sheet is formed between two perfectly matched molds, with one male, one female, that come together to shape the part from both sides. The molds close with heat and pressure, capturing every detail with high precision. This method is used when extremely accurate dimensions or textures are required, such as in automotive interiors or industrial panels. Because the molds are more expensive and take longer to make, matched mold forming is usually chosen for high-volume production or when aesthetics and exact fit are critical.

Mechanical Forming

Mechanical forming uses physical force, often from a plug assist or mechanical tool, to stretch the heated plastic into its final shape. The mechanical assist helps pre-stretch the plastic before it contacts the mold, reducing thinning in deep-draw areas and improving material distribution. This technique is especially useful for parts with high sidewalls or complex geometries. You’ll often find it used in packaging trays, containers, and parts that need consistent wall thickness.

1.3. Plastic Materials for Thermoforming

When it comes to thermoforming, not just any plastic will do. You need materials that can handle the heat, literally. That’s why thermoplastics are the top pick. These plastics get soft and bendy when heated, then harden up again once they cool. Perfect for shaping into trays, lids, panels, and all sorts of useful products. The best materials for thermoforming are easy to form, hold their shape well, and offer the right mix of strength, clarity, and resistance to impact, heat, or chemicals, depending on what you’re making. Here are some popular plastics used in thermoforming:

- PET (Polyethylene Terephthalate) – Crystal clear and strong, great for food packaging and drink containers.

- HIPS (High Impact Polystyrene) – Super easy to form, budget-friendly, and perfect for signs and disposable packaging.

- PVC (Polyvinyl Chloride) – Tough and chemical-resistant, but needs care when heating due to fumes.

- ABS (Acrylonitrile Butadiene Styrene) – Strong and impact-resistant — think tool housings or machine covers.

- PP (Polypropylene) – Light, flexible, and handles heat and chemicals like a champ.

- HDPE (High-Density Polyethylene) – Durable and water-resistant, ideal for bins, trays, and heavy-duty parts.

- PC (Polycarbonate) – Tough, heat-resistant, and clear — used where strength and visibility both matter.

2. Different Types of Thermoforming Mold

In thermoforming, selecting the right mold type is crucial for achieving desired part quality, structural integrity, and cost-effectiveness. Here are the common types of molds used in the thermoforming process:

2.1. Forming Mold

Forming molds are the primary tools used to shape heated plastic sheets into specific forms. They can be categorized into male (positive) and female (negative) molds.

Male (Positive) Molds

Male molds are shaped like a raised object — think of a bump or dome — and the heated plastic sheet is laid over it. Since the plastic stretches down around the outside, the interior dimensions of the finished part are easier to control.

This method is especially good for simpler shapes and parts where fine surface detail isn’t a priority. Male molds are quicker and cheaper to make, making them ideal for prototypes or short production runs. They usually produce a smooth, glossy exterior finish.

However, they come with limitations: the sides of the mold need to have a steeper draft angle to allow for easy removal, and material tends to gather more around the bottom edges, leading to uneven wall thickness, typically thicker at the bottom and thinner along the sides.

Female (Negative) Molds

Female molds work like a hollow cavity. The heated plastic sheet is pulled or pushed into the mold, allowing the plastic to conform to every surface and detail. This makes female molds perfect for applications where aesthetics matter, such as packaging with textures, logos, or sharp details on the outer surface. They offer better control over wall thickness and don’t require as steep a draft angle, which gives designers more flexibility.

However, female molds are generally more expensive and time-consuming to manufacture due to their complexity and precision requirements. Also, since the plastic is stretched into the mold, the bottom of the part may end up slightly thinner.

| Feature | Male (Positive) Mold | Female (Negative) Mold |

|---|---|---|

| Plastic Direction | Draped over the mold | Drawn into the cavity |

| Surface Detail | Basic, less detailed | High detail and textured finish |

| Cost | Less expensive | More expensive |

| Ideal Use | Simple shapes, prototypes | High-end parts, detailed designs |

| Mold Fabrication Time | Quicker to produce | Longer lead time due to complexity |

Plug-Assist Molds

Plug-assist molds incorporate a plug that pre-stretches the heated plastic sheet before it contacts the mold surface. This technique improves material distribution, especially in deep-draw applications, leading to more uniform wall thickness and reduced thinning in critical areas. Plug assists are commonly used with female molds and are essential for producing parts with consistent quality and structural integrity.

2.2. Tilting Mold

A tilting mold is built into machines that rotate or tilt the mold during forming. After heating, forming, and trimming, the mold tilts and pushes the finished part outward for stacking. This efficient motion allows finished parts, such as cups, trays, or containers, to be stacked directly as they emerge from the mold. It’s commonly used in high-speed production lines to streamline the process, reducing manual handling and increasing automation.

2.3. Punching Mold

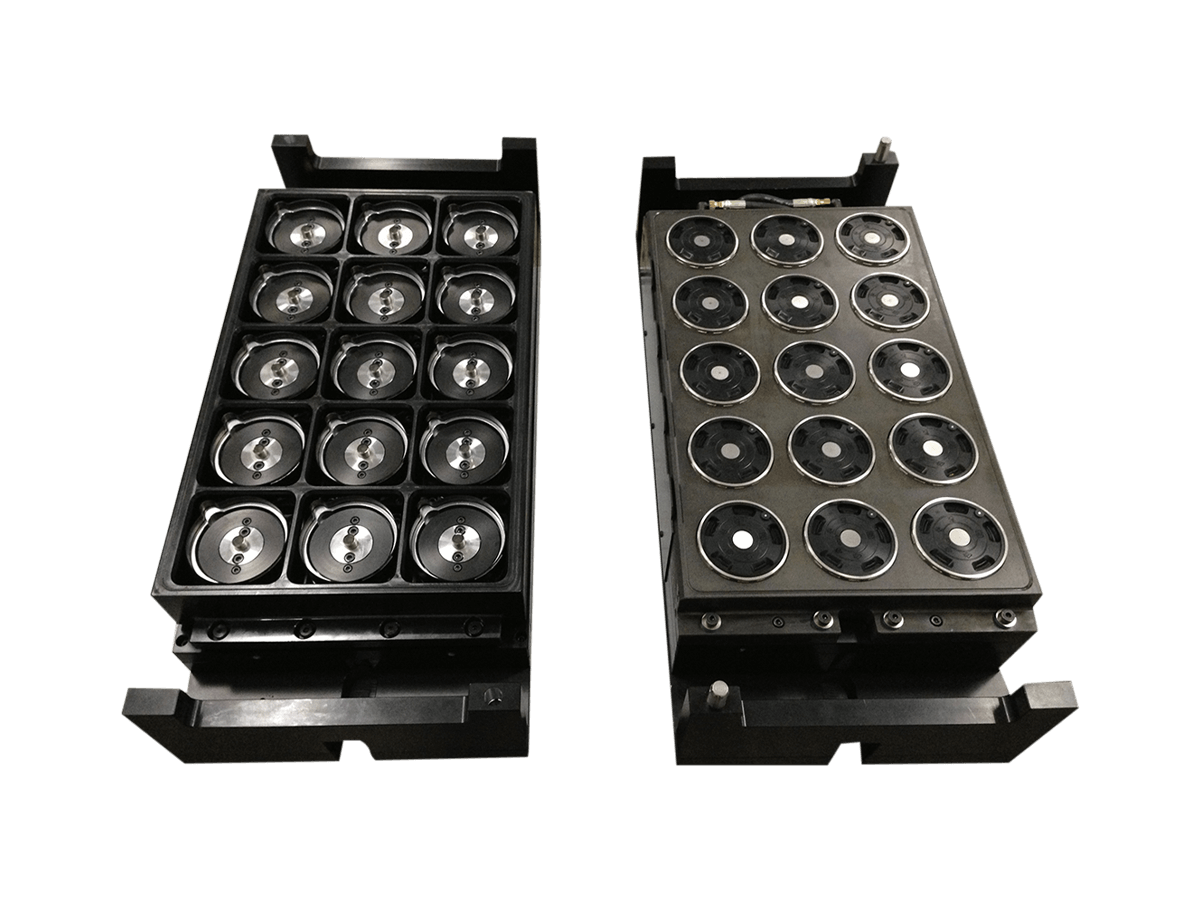

A punching mold consists of a male punch and a female die pair that cuts formed parts. Punching molds can be divided into hole punch tools and contour punching tools.

Hole punch tools are used to precisely cut holes in containers, trays, or lids, such as venting holes or sip-through holes, ensuring consistent placement and size.

Contour punching tools accurately cut along the outer shape of the product, producing clean and precise edges for lids, trays, or other shaped parts.

Thanks to our high-precision manufacturing, the main components of our punching molds are standardized, making it easy for customers to replace parts, manage tooling, and maintain consistent performance. This method is ideal for high-volume production where repeatable, accurate cuts are essential, delivering both high accuracy and fast cycle times.

2.4. Steel Rule Knife Mold

A steel rule knife mold uses a steel strip bent into the desired cutting shape, embedded in a frame. After the sheet is formed, it moves into the cutting station, where a bent steel rule knife serves as the cutting edge. The knife cuts along the outline of the part, leaving small tabs that keep the part attached to the surrounding sheet. This ensures the part remains in place for smooth transfer to the stacking station. While not as clean as punch-and-die cutting, this method balances precision, efficiency, and cost-effectiveness.

Here’s a quick comparison between a steel rule knife and punch-and-die cutting:

| Feature | Steel Rule Knife | Punch & Die Cutting |

|---|---|---|

| Cutting Style | Leaves small tabs around the part for handling | Clean cut, completely separates part from sheet |

| Cost | Lower | Higher |

| Best for | Small to medium production runs | High precision, high volume runs |

3. What to Consider When Designing a Thermoforming Mold

When it comes to thermoforming mold making, getting the design right is critical for both product quality and efficient production. One of the first things to consider is how many parts you plan to make. If you’re running a high-volume job, aluminum molds are a good choice because they’re strong, cool quickly, and last a long time. For prototypes or low-volume runs, you can go with resin or wood molds to save on cost.

Next, think about the forces involved. Thermoforming often uses vacuum or air pressure, and in some cases, mechanical plugs to stretch the plastic. Your mold needs to be strong enough to handle that pressure repeatedly without warping.

Temperature control is another big factor. Molds with built-in cooling channels help the plastic set evenly, which means less warping and more consistent part dimensions. Poor temperature control can lead to defects or slow production.

When your design has detailed features, like sharp logos or textures, the mold surface must be precise enough to transfer those details. A smooth mold surface will give you a glossy plastic finish, while a textured mold gives a matte look.

You also need to add a draft angle, usually around 3° to 5°, to make sure the part can be pulled off the mold without sticking. Without this, the plastic can tear or get stuck. Corners should be slightly rounded instead of sharp, as this helps the plastic flow evenly and reduces thinning, which keeps the part strong and durable.

4. Equipment Yi Jhih Uses for Making Thermoforming Molds

At Yi Jhih, precision starts with the machines. Our facility houses over 23 high-end precision grinding machines, along with advanced EDM, jig grinding, and CNC milling equipment sourced from top global brands like Hauser, Charmilles, and Mikron.

Among them are 5 high-speed machining centers, which are essential for delivering superior surface finishes and dramatically improving processing efficiency. These machines handle high-speed cutting and surface polishing, producing molds with smooth, flawless surfaces and intricate details.

Key components operate within tight tolerances as fine as 0.002 mm, ensuring consistency and stability throughout the tooling. With over 95% of components made in-house, our vertically integrated setup guarantees not only speed and flexibility but also exceptional quality control at every step.

Check information about our facilities here!

5. Your Only Source for High-Precision Thermoforming Molds: Yi Jhih

At Yi Jhih, you would find more than just thermoforming molds. We deliver confidence, consistency, and craftsmanship you can rely on. Backed by over 50 years of industry experience, a team of highly skilled experts, a high-performance manufacturing process, and powered by world-class European precision machinery, we are proud to support the food packaging industry with tools engineered for performance and built to last. More than US$17 million in advanced equipment, we deliver molds that combine long-term stability, precision, and performance.

Our Core Strengths:

- Unmatched Precision: Major mold components, including male punches and female dies, are held within 0.002 mm, while the guide post and bush achieve 0.001 mm accuracy, ensuring consistent quality and durability.

- High Vertical Integration: With over 95% of components produced in-house, we provide flexible delivery schedules and superior quality control.

- Stable & Skilled Team: Exceptionally low turnover—only two employees left in the first 30 years—gives us unmatched consistency and craftsmanship.

- Proven Project Experience: Decades of successful collaboration on leading platforms, such as KIEFEL 6.1, ILLIG RDM76K/76Kb, and GABLER M100.

- Optimized Mold-Making Process: Backed by 50 years of mold manufacturing expertise, we have mastered the process know-how to ensure every mold delivers superior precision, cutting performance, and long-term stability—allowing clients to operate with confidence and consistency for years.

- Trusted Values: For 50 years, we’ve upheld integrity, honesty, and uncompromising commitment to our clients’ interests.

Our mission is simple: to deliver precision molds that ensure long-term reliability and superior cutting quality, project after project. Let’s take your packaging to the next level. Contact us today to explore how our precision thermoforming tools can give your business a real advantage. We’re here to listen, collaborate, and create solutions that fit perfectly.

You might also be interested in knowing more about: